4030 Model CO2 Laser Engraving Machine

Professional desktop design, good appearance, compact structure, taking small space.

For more information, please contact us freely.

Machine Features

1. Professional desktop design, good appearance, compact structure, taking small space.

2. There are different height lawyers for machine table installation. Machine table height can be selected according to item’s height.

3. Advanced DSP control system, fast speed and easy operation.

4. High speed engraving greatly improves the processing efficiency.

Applicable Materials

Able to engrave and cut: wood products, paper, plastics, rubber, acrylic, bamboo, marble, double-color sheets, glass, wine bottles and other non-metal materials

Application Industries

Advertising signs and boards, arts and crafts, awards and trophies, paper-cutting, architectural model , lights and lamps, printing and packaging, electronics, photo

frames and albums, garment leather and other industries.

Model: | Rofer-E-4030 Desktop Mini |

Laser type: | CO2 laser tube, water-cooled |

Laser power: | 50-watt/60-watt |

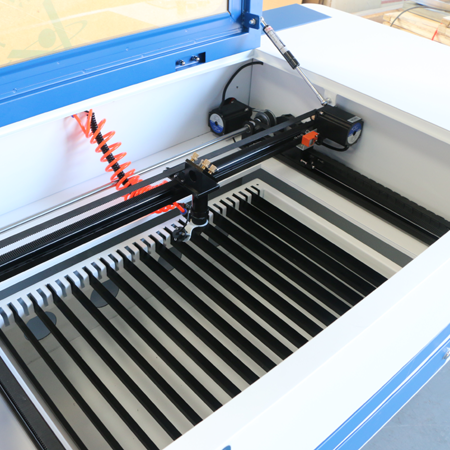

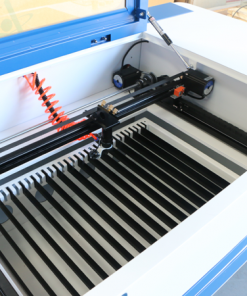

Working area: | 400mm x 300mm (1.3 feet x 1.0 feet) |

Engraving speed: | 0-6000cm/min |

Cutting speed: | 0-5000cm/min |

Repeating location: | ≤±0.01 |

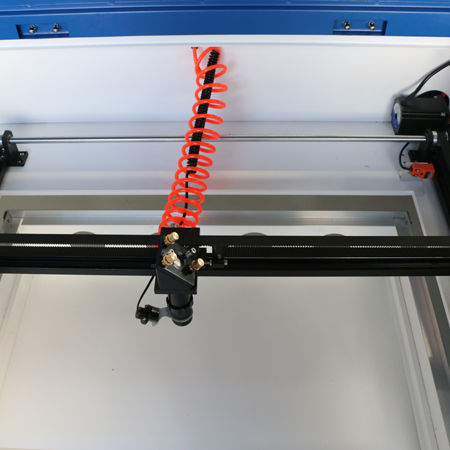

Transmission type: | Belt transmission |

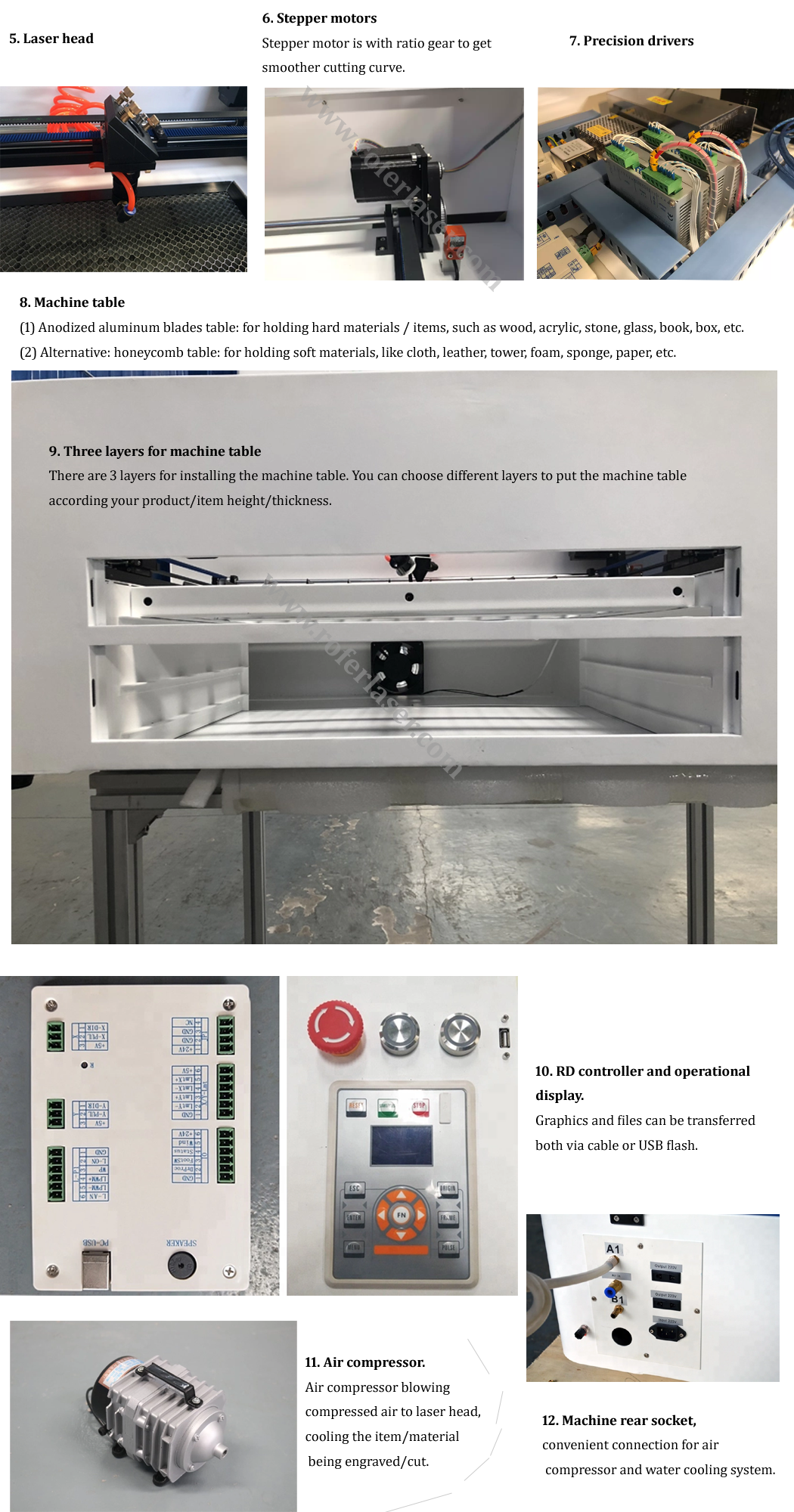

Driving system: | stepper motors and drivers |

Machine table: | Anordized aluminum blade table (alternative: honeycomb table) |

Graphic format supported: | BMP, HPGL(PLT), JPEG, DXF,AI, DST, etc. |

Software supported: | CorelDraw, AutoCAD, Photoshop, Tajima |

Control system: | Ruida control system |

Working voltage: | 220V, 50Hz-60Hz |

Installation & training

After the machine reach the buyer’s site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the

help of the buyer. Buyer should pay for our engineer visa fee, air tickets, accommodation, meals etc.

Training:

The common protection knowledge of laser safety

The basic principle of module and the structure of laser cutting machine

The operation skills of laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Installation & training time is about 5 to 7 days.

Warranty & Service

1). 12 months warranty for the whole machine

2). 8 months warranty for the co2 laser source

3). Life-long maintenance

4).In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair

for free,the parts need to be replaced will be provided from seller for free(Except the quick-wear part).

5)After warranty we will still supply lifetime maintenance in free. Just if parts broken, we will replace with charge.

6).After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible.

相关产品

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE