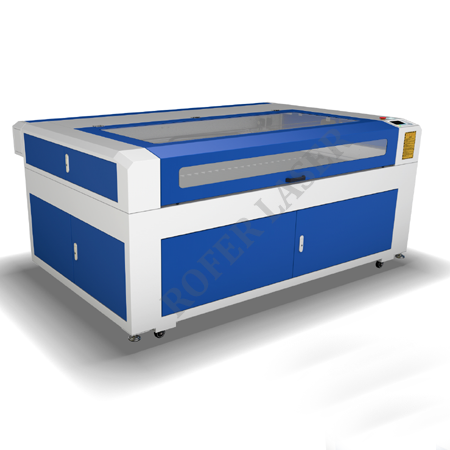

1610 Model CO2 Laser Engraving Cutting Machine

Rofer-E-1610 CO2 laser engraving machine with 60W, 80W, 100W, 130W, 150W or 180W laser power is designed for engraving on wood, fabric, leather, glass, acrylic, paper, plastic, stone, etc. The best CO2 laser engraver machine is widely used in signs, arts, crafts, gifts, shoes, toys, garments, packaging and paper industry.

For mor information, please contact us!

Rofer-E-1610 CO2 laser engraving machine with 60W, 80W, 100W, 130W, 150W or 180W laser power is designed for engraving on wood, fabric, leather, glass,

acrylic, paper, plastic, stone, etc. The best CO2 laser engraver machine is widely used in signs, arts, crafts, gifts, shoes, toys, garments, packaging and paper

industry.

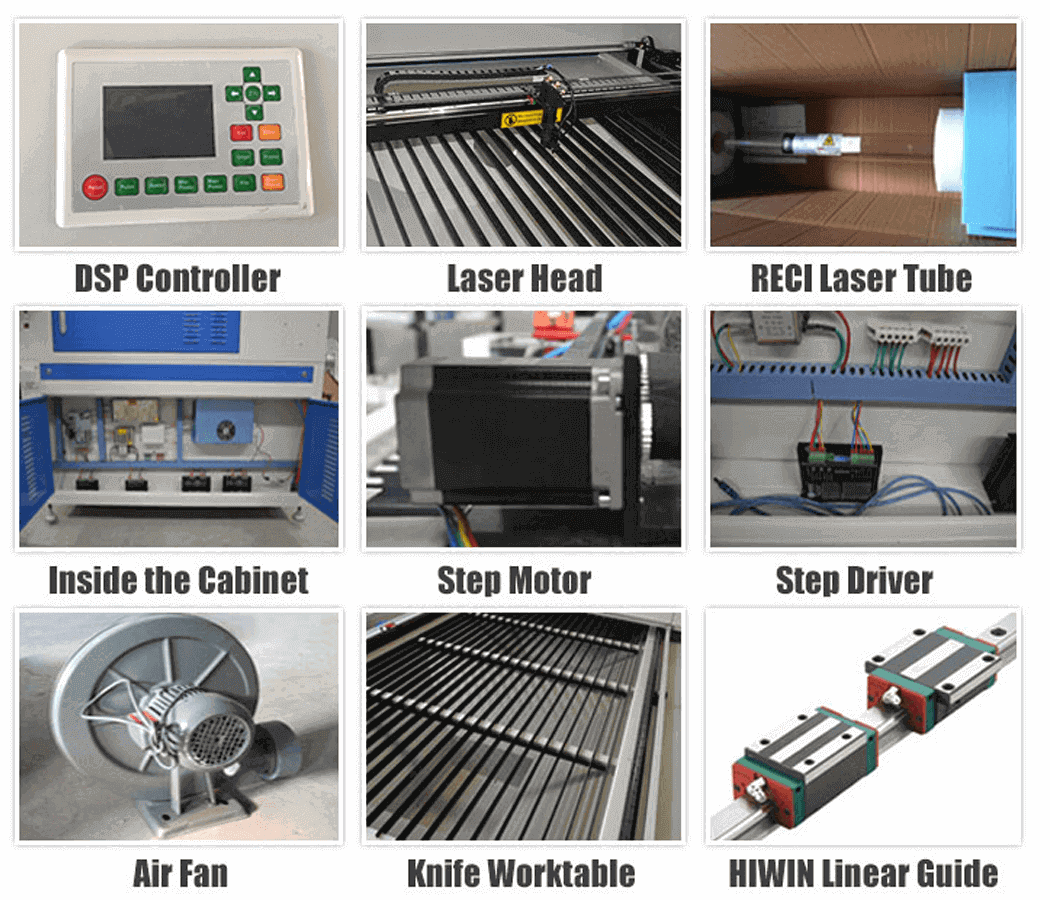

Rofer-E-13610 CO2 laser engraving machine is equipped with a precision water cooled CO2 laser which can engrave on almost any non-metal materials surface.

The CO2 laser engraver machine can also be used for cutting many different non-metal materials. With the optional cylinder rotary attachment, you can engrave any

cylindrical object, such as cup, brush pot, musical instrument, and so on. The CO2 laser engraving system supports multiple graphic formats, such as PLT, DXF, BMP,

JPG, GIF, PGN, TIF, and so on. The CO2 laser machine is equipped with DSP control system for CorelDraw, AutoCAD and other advanced software.The CO2 laser

engraver is compatible with WIN10, WIN8, WIN7, Windows Vista and Windows XP.

Model | Rofer-E-610 |

Laser Power | W2(90W)/W4(100W)/W6(150W)/W8(180W) |

Laser Type | CO2 laser |

Working Area | 1300*900mm |

Application | cutting&engraving on non-metal materials |

Control Software | DSP control system |

Software | Laserwork |

Cooling Type | Water cooling |

Driving System | Stepper motor |

Operating Temperature | 0 – 45ºC |

Table | Blade worktable/Honeycomb worktable |

WARRANTY | 1 year limited warranty (excludes shipping/consumable items) |

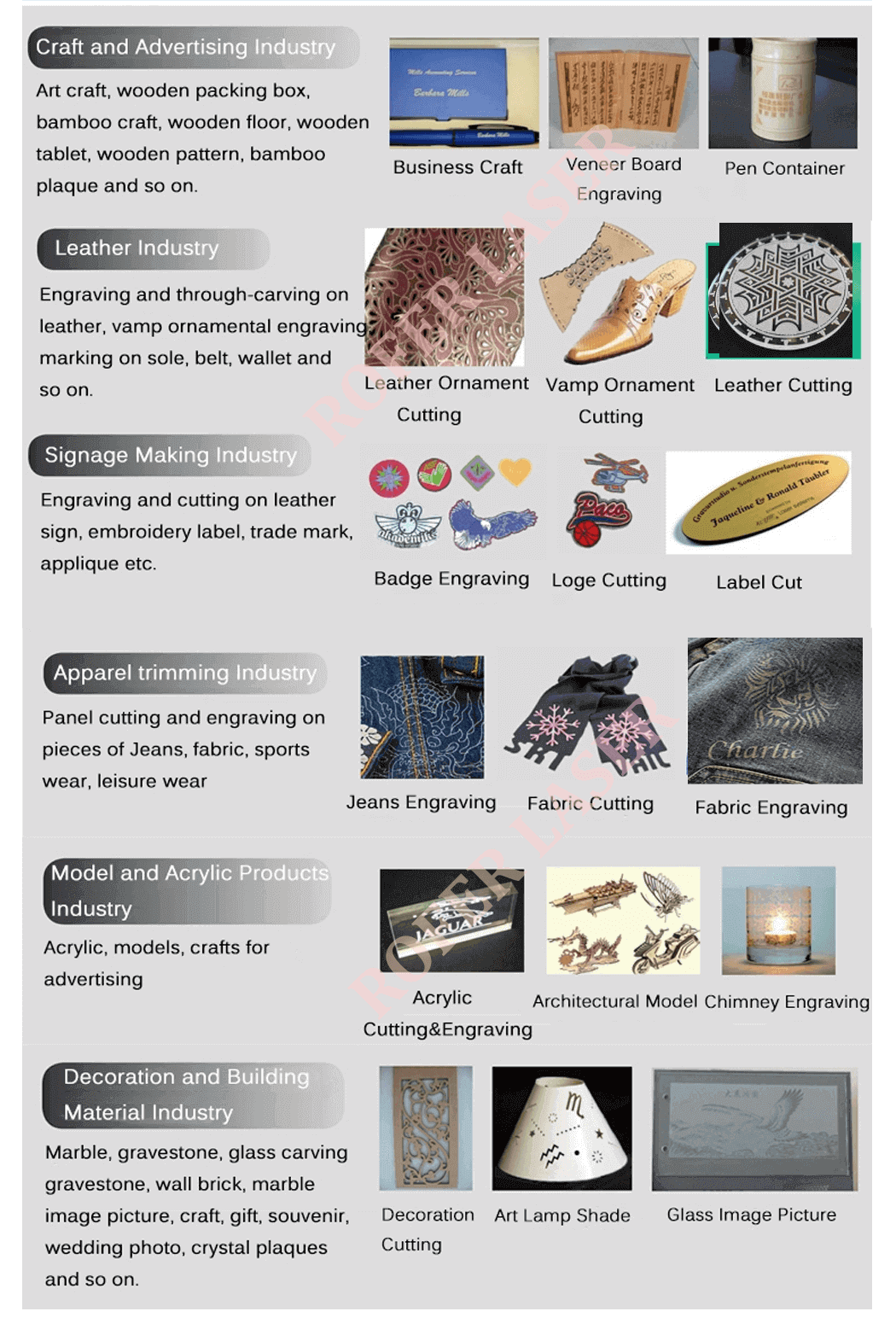

CO2 laser engraving machine is mainly for non-metals material and industry application.

The CO2 laser engraver is used for wood engraving, industrial prototyping, industrial engraving, sign making, medical part engraving, aerospace, architectural

modeling, specialty advertising, plastics fabricating, flexo, point of purchase, rubber stamps, picture framing, gift manufacturing, bar coding, gasket cutting, textile

cutting, puzzles, cabinetry, awards recognition, personalized pens, door pulls, scroll patterns cutting, games, toys, finger joints, inlays, overlays, fraternity paddles,

music boxes, light switch plates, jewelry boxes, parts engraving, router templates, desk sets, scrap booking, photo albums, jewelry, crafts, Italian charms.

Applicable Materials:

Wood, acrylic, stone, bamboo, organic glass, crystal, plastic, garments, paper, leather, rubber, ceramic, glass, and other nonmetal materials.

Applicable Industries:

Advertisements, gifts, crafts, arts, toys, shoes, computers, model making, garments, building, paper, packaging industry.

Installation & training

After the machine reach the buyer’s site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the

help of the buyer. Buyer should pay for our engineer visa fee, air tickets, accommodation, meals etc.

Training:

The common protection knowledge of laser safety

The basic principle of module and the structure of laser cutting machine

The operation skills of laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Installation & training time is about 5 to 7 days.

Warranty & Service

1). 12 months warranty for the whole machine

2). 8 months warranty for the co2 laser source

3). Life-long maintenance

4).In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair

for free,the parts need to be replaced will be provided from seller for free(Except the quick-wear part).

5)After warranty we will still supply lifetime maintenance in free. Just if parts broken, we will replace with charge.

6).After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible.

相关产品

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE

CO2 LASER ENGRAVING MACHINE