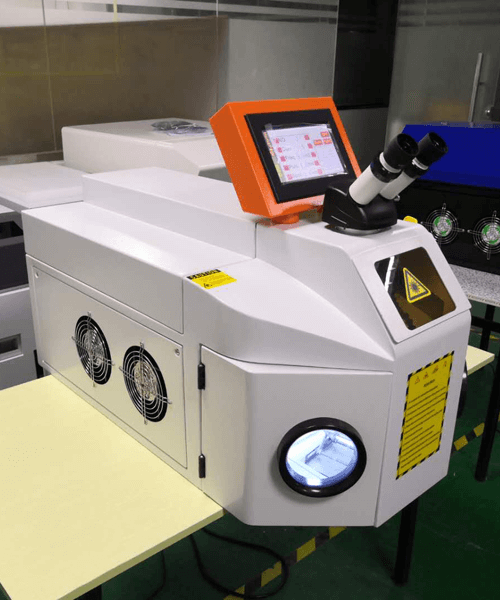

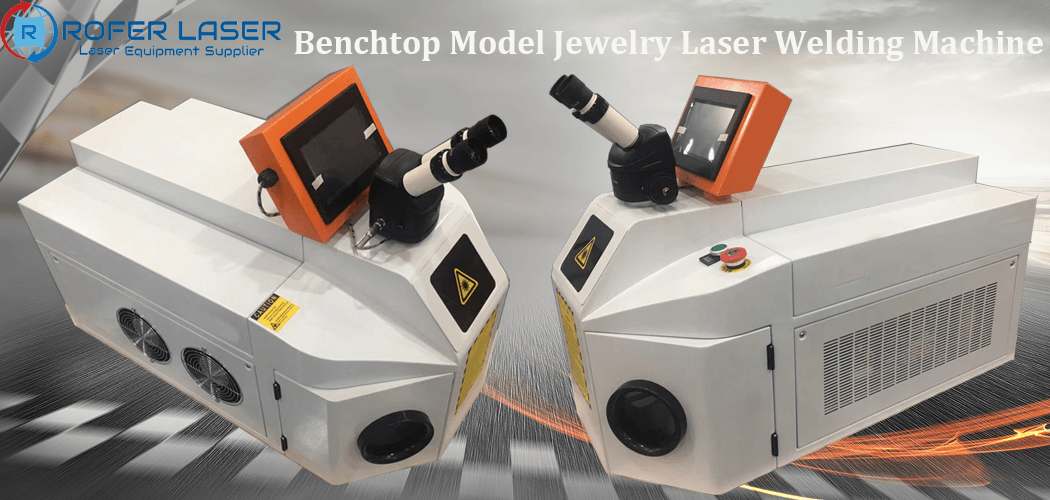

Benchtop Model Jewelry Laser Welding Machine

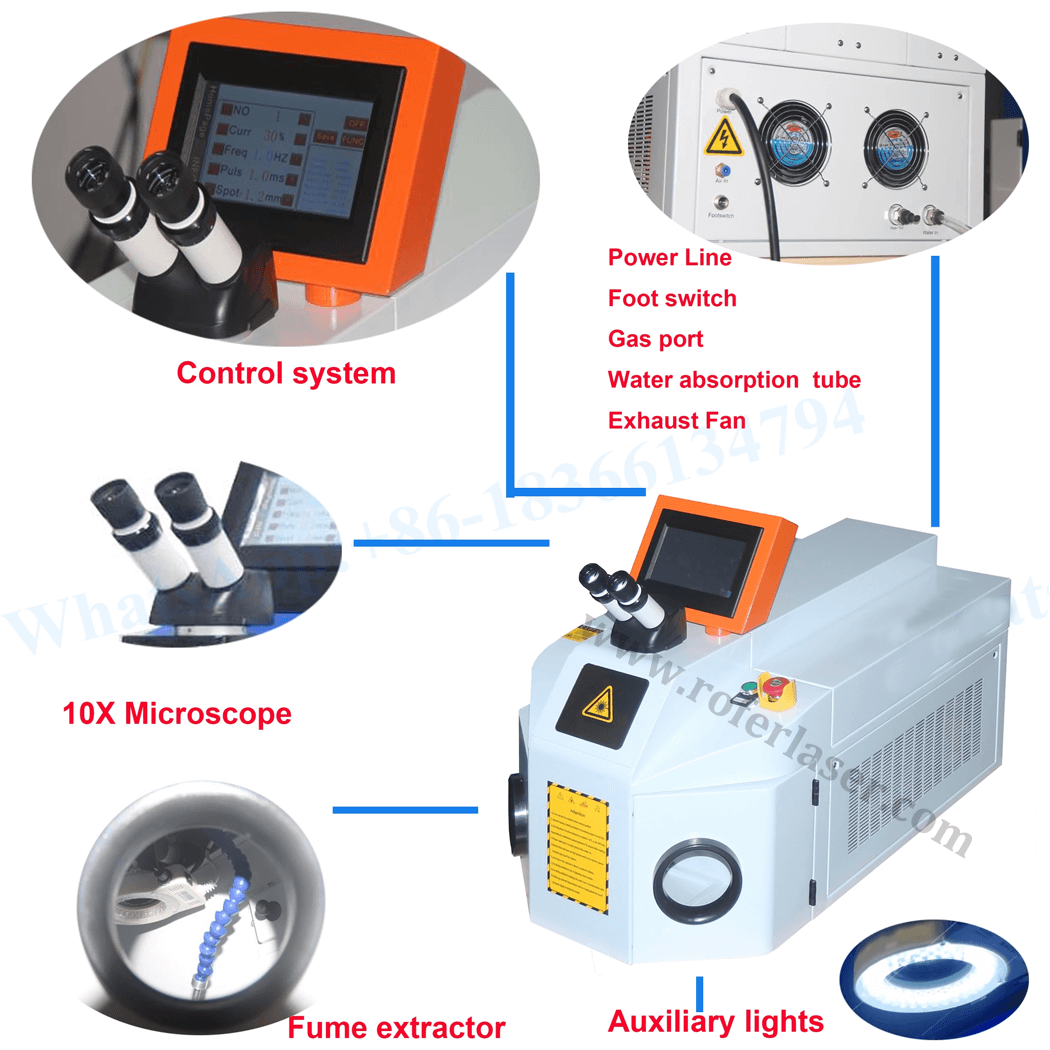

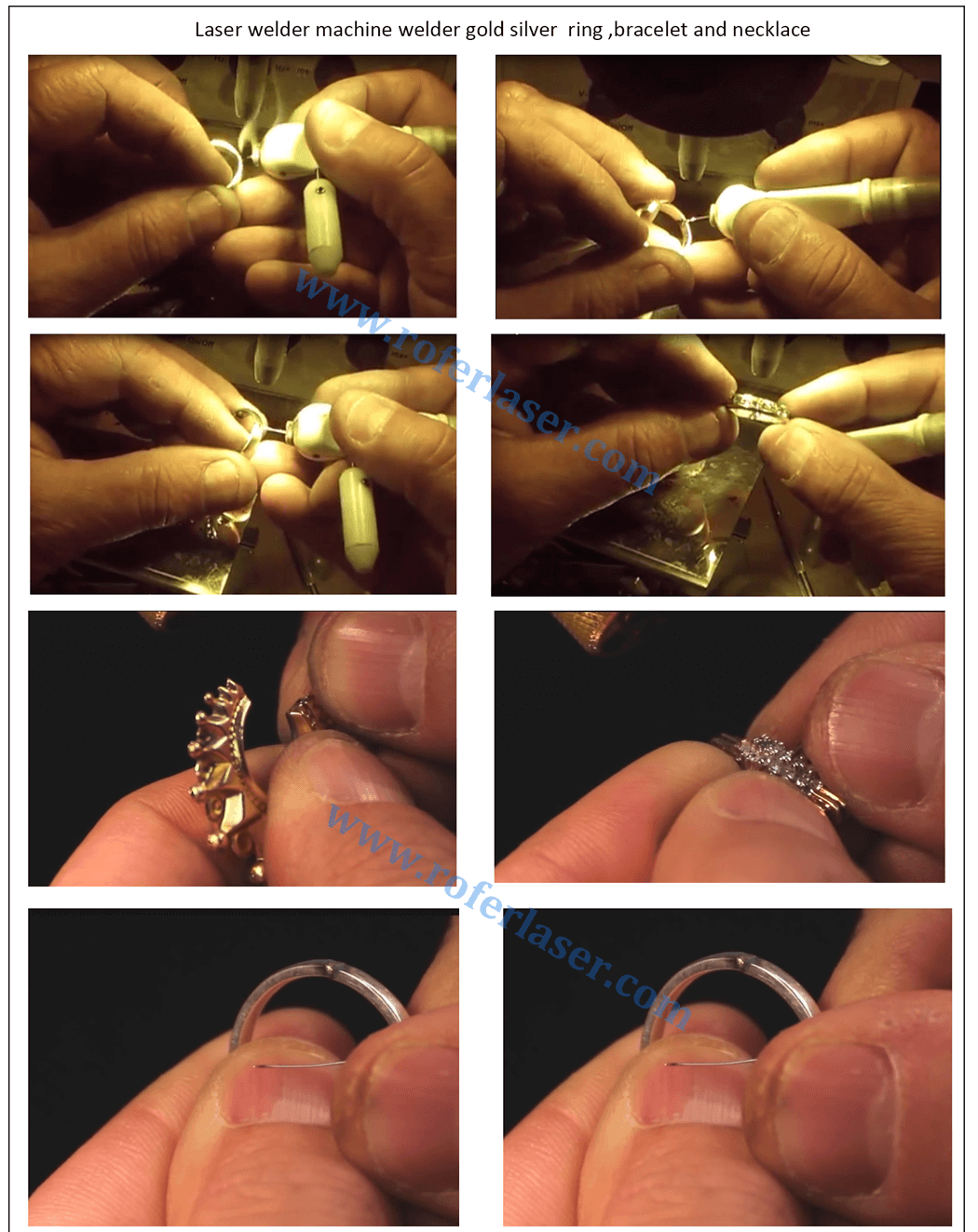

Jewelry spot welding machine with External chiller is specially developed for laser welder of jewelry by ROFER LASER and mainly used in perforating and spot welder of gold and silver jewelry. It is of touch screen type, adopting new style power source, elaborating operation, and optimizing the optical path, with high photoelectric conversion efficiency, high stability, small size, high configuration and other characteristics.

For more information, please contact us freely!