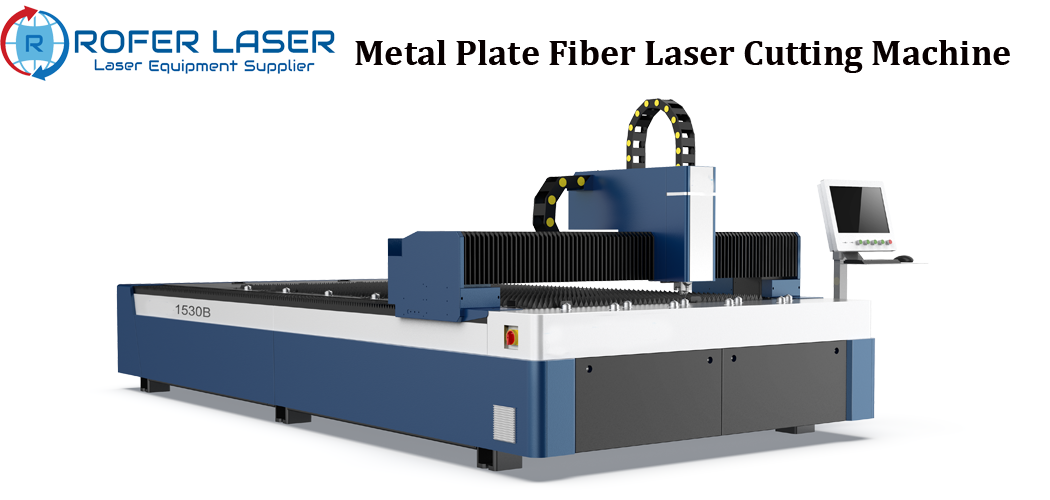

Metal Plate Fiber Laser Cuting Machine

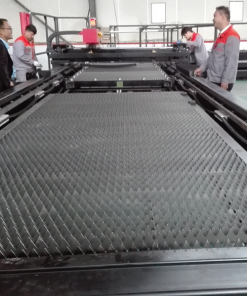

The is our metal plate fiber laser cutting machine, the metal laser cutter is suitable for stainless steel, carbon steel, aluminum, copper, brass, gold, silver, etc. Fiber laser cutters from ROFER LASER can cut varied materials and thicknesses with high efficiency and high quality. To reduce the cycle times and increase thickness of metals, we have 750W, 1000W, 1500W, 2000W, 3000W, 4000W, 6000W and 8000W for choose. If you want to get one similar laser metal cutting machine or need more information about it, don’t hesitate to tell us.

![]()

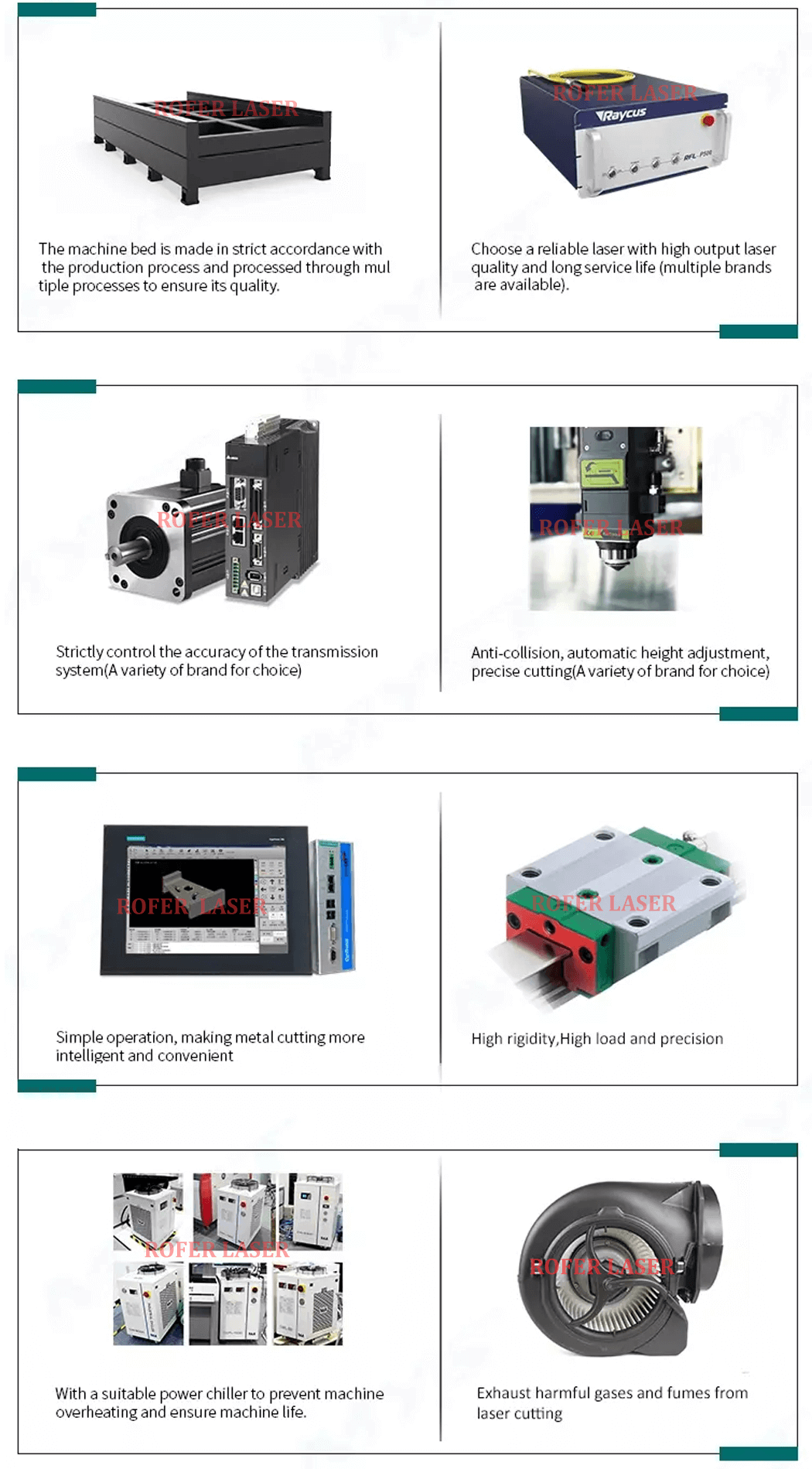

1.High speed: 40m/min, two driver, synchronous high speed move.

2.Leapfrog cutting: Improve the cutting speed, processing efficiency and accuracy.

3.Scan cutting: Short distance cutting without head lifting.

4.Cutting and marking functions: Power can be set with two layers, one cut and another mark. Buyer can cut and mark together on one metal part.

5.Automatic search edge function: If metal sheet put slanting, machine can auto detect, and auto adjust cutting, less waste and no need to replace material.

6.Power off cutting memory: When suddenly power off, software has memory of cut stop point, after power on, you can start cutting from the break point.

7.Install Proportional Valve: Use software to change the air and control the air pressure automatically, no need to change the air manually, it can save much time.

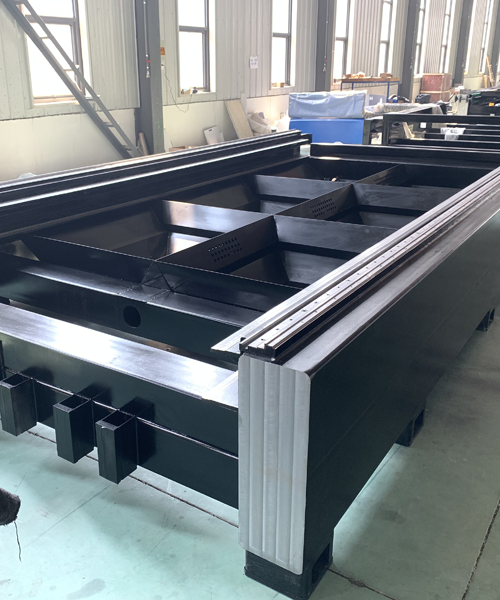

8.Stable working table: Use 16mm thick steel side board, around 3.5 tons in weight. Dual drive, aging treatment, stress relief test to ensure long time fast running

without changing shape.

9.Air condition for control cabinet: Cooling for electronic parts and laser power supply, make sure control cabinet temperature at under 45℃ which extend the life of electronic

devices and save the power for the factory.

![]()

Items | Details |

Laser type | Fiber laser |

Laser working media | Fiber |

Laser wavelength | 1070nm |

Max. output power | 750W-6000W |

Cooling mode | Water cooling and protection system |

Beam quality | <0.373mrad |

Working range of Z axis | 120mm/250mm |

Workbench axial positioning accuracy | ≤±0.02mm/m |

Workbench Repositioning Accuracy | ≤±0.02mm/m |

Cutting Speed | ≤40m/min (Depends on material) |

Workbench maximum load (sheet table) | 1200KG-4000KG |

Rated parameters of power supply | 3 Phase AC 380V 50Hz |

Equipment electric power | 10-20KW |

Total power protection class | IP54 |

Electric oil pot | Timely quantitative automatic filling |

Acceleration speed | 1G (1800W) |

Empty line speed | 100m/min |

Single positioned accuracy | <0.03mm |

![]()

Material :

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet,

Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet,

Metal Plate, Tubes and Pipes, etc

Industry :

Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters,

Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting,

Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

![]()

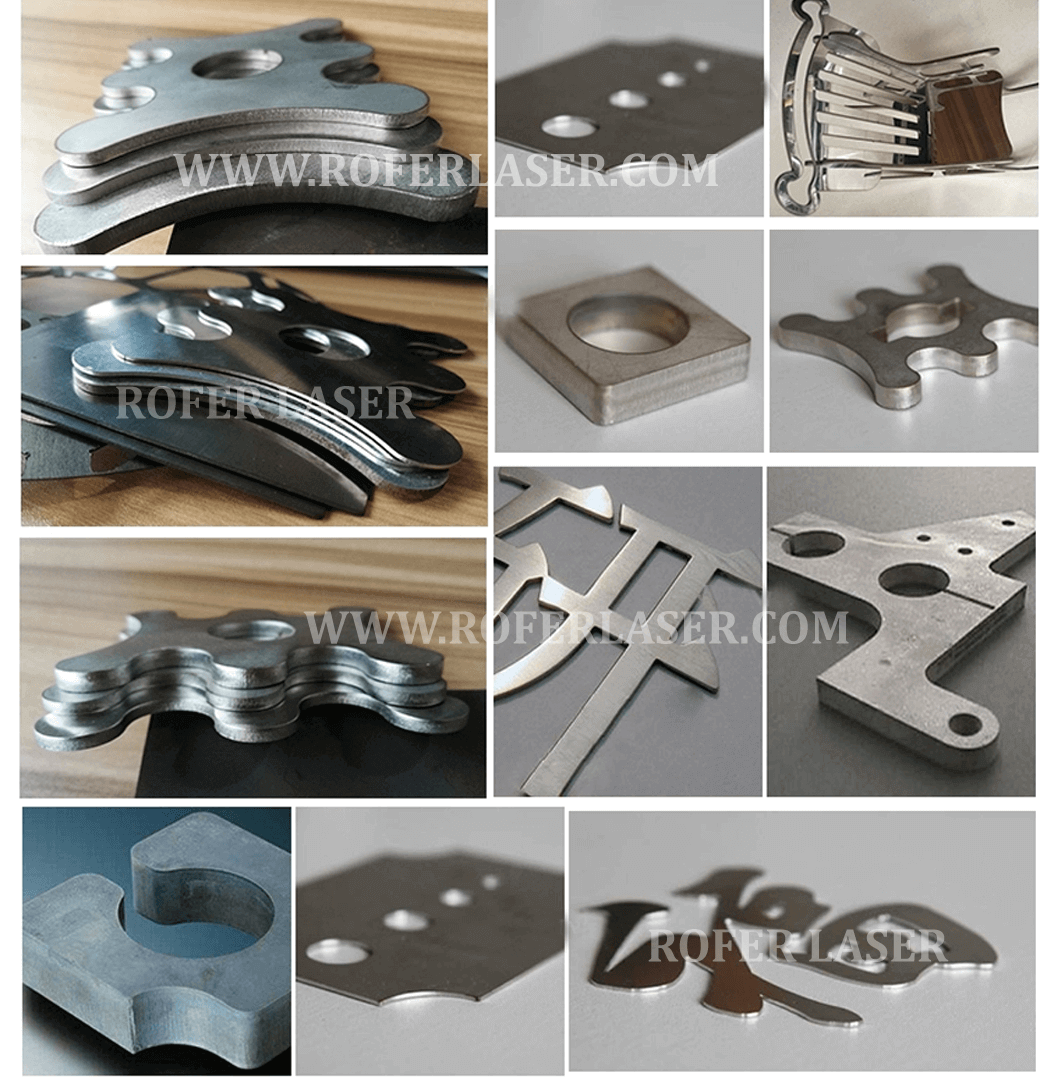

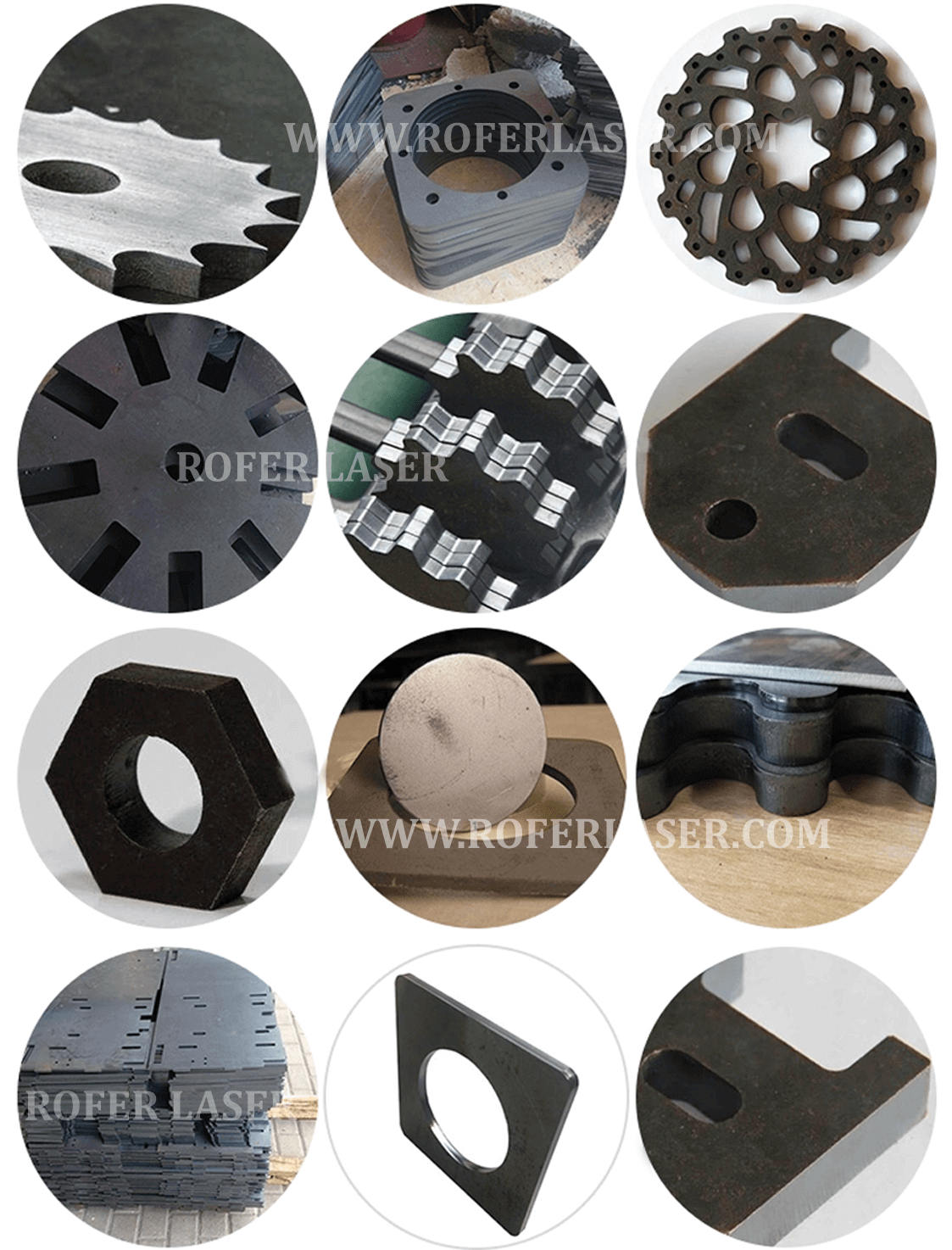

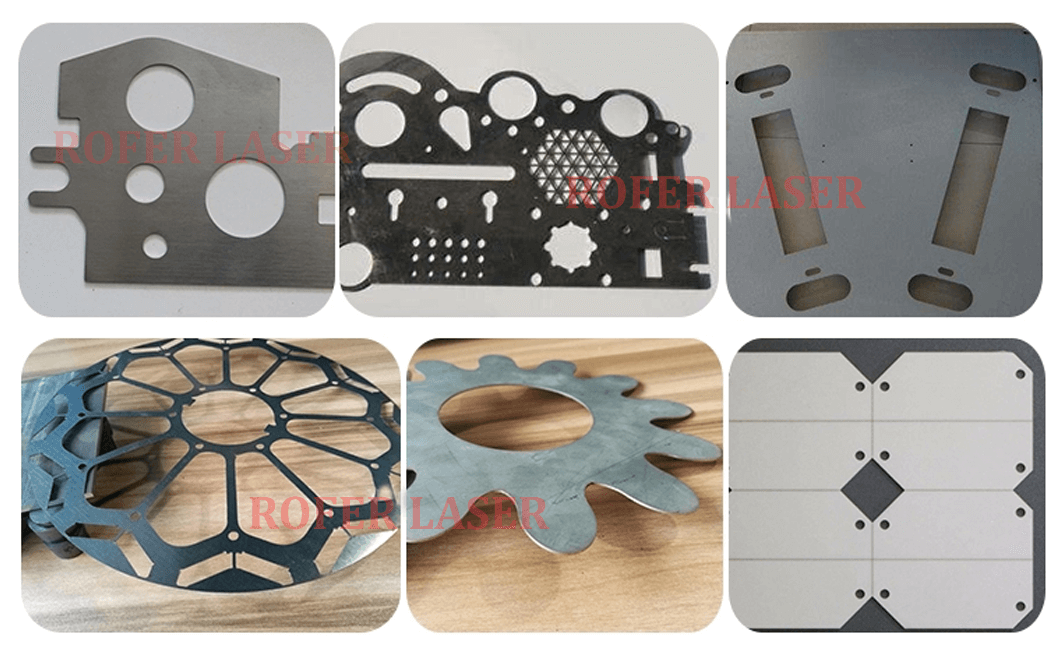

Stainless steel cutting damples :

Carbon steel cutting samples :

Galvanized sheet cutting samples :

Brass&Copper sheet cutting samples :

![]()

![]()

![]()

![]()

Installation & training:

After the machine reach the buyer’s site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the

help of the buyer. Buyer should pay for our engineer visa fee, air tickets, accommodation, meals etc.

Training:

The common protection knowledge of laser safety

The basic principle of module and the structure of laser cutting machine

The operation skills of laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Installation & training time is about 5 to 7 days.

Warranty & Service :

1). 24 months warranty for the whole machine

2). Life-long maintenance

3).In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair

for free,the parts need to be replaced will be provided from seller for free(Except the quick-wear part).

4)After warranty we will still supply lifetime maintenance in free. Just if parts broken, we will replace with charge.

5).After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible.

相关产品

FIBER LASER CUTTING MACHINE

FIBER LASER CUTTING MACHINE

FIBER LASER CUTTING MACHINE